At a recent meeting I attended in Milan, Italy a great deal of discussion was centered on a concept that went by the name of “Circular Economy Package” – CEP. It has been around for several years – initiated by the European Union – but only recently has it started to show signs of gaining some teeth.

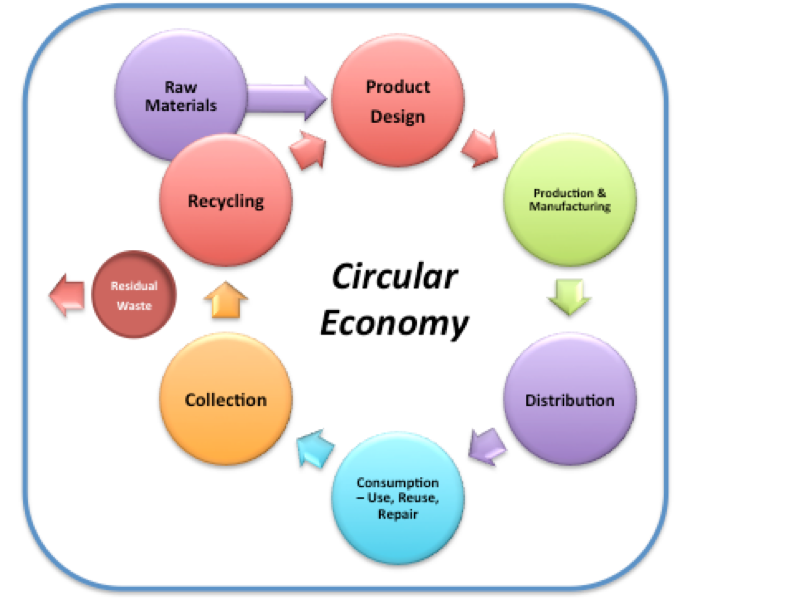

So, what exactly is a Circular Economy? A quick look at the following graphic will help you understand its components and the various interrelationships that exist between them.

Casual observation will quickly conclude that the CE is not linear in nature. Waste throughout the world has constantly grown at an exponential rate over the centuries and this is because all global economies have used a “take – make – consume and dispose” model for growth. This is a linear model that erroneously assumes that resources, in general, are abundant, readily available, and inexpensive to dispose of. Unfortunately, existing food service industry infrastructure, historical business models and technology, along with established channel dynamics and behavior are keeping existing economies “locked-in” to this linear model. There are many potential reasons why, which I will address in a later article.

In the circular economy model shown on the previous page, its implementation means re-using, repairing, refurbishing, and recycling existing products and materials. What historically has been considered “waste” should, and can be turned into a resource. Simply stated, the primary aim of a CE is to look beyond waste and to close the loop of the circular economy. To accomplish this it means that all resources need to be more efficiently and effectively managed throughout their entire life cycle.

Well thought-out and executed circular economies are designed to keep the added value in products for as long as feasibly possible, and thus eliminating, or drastically reducing waste. They keep valuable resources within the economy when a product has reached the end of its useful life so that they can be productively used over and over again, and hence create additional value.

So, what are the implications of this “new economy” to manufacturers and all of the various other channel constituents within the food service industry? First and foremost, it necessitates a change in company culture, or philosophy. A Circular Economy approach is to “design out” waste, and that typically involves innovation throughout the entire value chain, and not just relying solely on solutions at the end of the life cycle of a product.

Let’s look at some specific “adjustments” that equipment manufacturers within the food service industry will have to make if they truly want to embrace the Circular Economy philosophy.

- Lightweighting – as the name implies, this means reducing the quantity of materials that is required to make a particular product. It also means finding materials that are lighter in weight than that which is being used now. The global auto industry has been doing this for years as they continuously try to find ways to reduce the weight of the cars they produce as one of many means to increase the fuel economy of their vehicles.

- Increased Durability — Lengthening a products’ useful life will have a direct impact on reducing the amount of residual waste.

- Energy Efficiency – This is a “two-pronged” component. First, companies will have to look at finding ways to reduce the amount of energy that they are consuming in the actual product of their products, and secondly, they will need to design products that consume less energy during its use phase.

- Material Substitution – This refers to finding ways – through design and intelligent sourcing – to reduce the use of materials that are deemed hazardous or difficult to recycle in products as well as in the production process.

- Recyclates – When designing products look to use (where possible) raw materials that can be easily recycled.

- Eco Design – Simply stated, companies need to design products that are very easy to maintain, easy to repair, and easy to re-manufacture and / or recycle.

- Maintenance & Repair Services – Manufacturers need to develop the necessary services and preventative maintenance programs for the food service operators.

At a minimum, all of the above should be considered as starting-points in the design of production processes and the final products themselves. Products can be redesigned to last longer, easily repaired, upgraded, remanufactured, or eventually recycled, instead of being simply thrown away.

There is much more that can be said and written about the Circular Economy Package. With more specific “requirements” and recommendations expected to be released in Paris towards the end of this month (November 2015) and early next month (December 2015), I will provide further thought and insight into this subject after having the opportunity to mull through and digest the Commission’s recommended set of Action Plans. Stayed tuned.

Much of the material for this article came from the “Communication From The Commission To The European Parliament, The Council, The European Economic And Social Committee And The Committee Of The Regions” – European Commission.