by: Douglas K. Fryett & Keith Warren

Supply chain management, as the name implies, is all about managing something that is rather “static” in nature. By simple definition, it is about “managing” an existing model designed to provide a certain degree of “value” to all channel participants that are part of a particular supply chain. Food service equipment and supply manufacturers have their upstream vendors who are supplying the various raw materials and components necessary to manufacture and assemble their particular family of products. These manufacturers, in turn, have their downstream channel partners as well – equipment and supply dealers, food distributors, design consultants, and service agencies – who are “responsible” for providing an “efficient” go-tomarket strategy for the aforementioned various manufacturers.

Value chain strategy takes on an entirely different complexion than that of supply chain management. By nature, “value” is a very dynamic word — it is constantly changing – as value is always in the eyes of the beholder. In other words, it means different things to different people, or constituent groups, and at different times. As such it requires a significantly greater degree of nimbleness, cooperation between all of the various value channel constituents, and attention being paid to it by all members of the value chain.

Supply chain strategy or value chain strategy? It will be important that organizations seriously consider the need to start making the shift to a value chain strategy business model from the more traditional supply chain management model if it is their desire to optimise their economic and brand position within the marketplace. To put it another way, to achieve sustained growth, companies should be concentrating their strategic and tactical efforts on developing and executing strategies that create value for all of the various channel constituents rather than focusing on trying to develop that rather elusive sustainable competitive advantage. Because in today’s marketplace there is no such thing as a truly sustainable competitive advantage.

Putting it in the context of the food service industry, the biggest challenge facing today’s food service leaders is finding new and innovative ways to create and sustain value for the end-user / operator base and not pursuing a strategy of trying to achieve a sustainable competitive advantage.

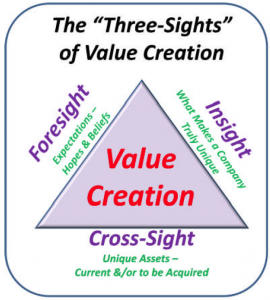

But how can a company create sustainable “value” for its constituents? How can it make value creation one of its corporate values and institutionalize it? Todd Zinger, in a recent Harvard Business review article, proposes that value can be created through the convergence of three “sights” – foresight, insight, and cross-sight. Let’s take a closer look at these “sights” that he has identified and relate them to our industry.

Foresight should clearly articulate a company’s expectation and beliefs regarding the short and longterm future of the industry in which it finds itself. In the context of the food service industry, it should clearly predict future consumer tastes and/or consumer demand; operator issues and drivers; take into consideration the use of current technologies and the emergence of new technologies. It should also anticipate the reaction of its competitive rivals. Foresight also suggests those asset acquisitions, investments, and strategic actions and alliances that will prove essential in a company’s predicted future state of the industry in which it is participating.

Foresight should clearly articulate a company’s expectation and beliefs regarding the short and longterm future of the industry in which it finds itself. In the context of the food service industry, it should clearly predict future consumer tastes and/or consumer demand; operator issues and drivers; take into consideration the use of current technologies and the emergence of new technologies. It should also anticipate the reaction of its competitive rivals. Foresight also suggests those asset acquisitions, investments, and strategic actions and alliances that will prove essential in a company’s predicted future state of the industry in which it is participating.

Today, there is a massive convergence of industry and non-industry dynamics – new technologies; the increased proliferation of existing technologies; sustainability and all of the “peripherals” associated with sustainability; the increased use of analytics based management; changing consumer “demands,” changing end-user / operator dynamics, to name but a few that are, and will continue to shape the global food service industry.

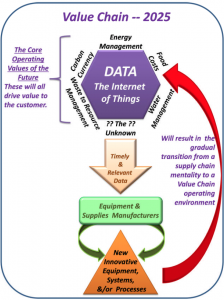

So, where is the “natural” beginning of this “revolution” of sorts? The “internet of things” and “big data” are widely acknowledged to be the drivers. They will be the hub of the technical developments for the foodservice industry, as it will be for most industries. Ultimately, the ability to share and interrogate data amongst all constituent groups will lead to catering equipment that is intuitive to use and hence become even more important to operators. In fact, the data revolution that society is “embarking” on is the contemporary equivalent to the industrial revolution. Those who adopt will significantly increase their chances of success. Those who don’t, well …

Key to this development will be the needs of the food service industry operators / end-users. This important segment will be driven by the essential requirements of the need to manage their businesses more closely. This will include their cost base, carbon footprint, and equipment related issues such as service scheduling. Carbon may very well become the currency of the future and a key business differentiator. The Kyoto agreement was signed up to by the world’s leading nations. Europe’s 2030 and 2050 energy roadmaps show how this will evolve with the development of European supply networks. And localized smart metering at the unit level will place significant focus on energy management and carbon related issues. This will inevitably push the use of technologies seen in other industries. In the context of our industry, this will drive innovation and invention with commercial equipment needing to match the efficiency and operational demands of the operator customer.

Today we are seeing legislation delivered through the “Energy related Products” Directive (ErP) in the form of Implementing Measures for commercial refrigeration, dishwashers, ovens and hobs. Its purpose is to reduce the energy use of equipment within these categories by setting minimum energy performance standards which must be achieved.

With the need to reduce the world’s use of resources, carbon has become the lowest common denominator for all the products that consumers and business use. In business terms, there will be further reliance placed on businesses to measure their carbon “bottom line” with as much vigour and aggressiveness as their financial one. The carbon foot-printing of all products will enable this.

The limited and more costly energy resources available will mean further development of dynamic efficiency products that can be remotely managed on-line by the manufacture and/or by the operator. This will inevitably dominate this sector’s development. Energy companies may wish to be the supply partner for food service equipment and as such proactively manage the energy use of such equipment that it is, itself selling into the marketplace. This creates yet another supply channel (value channel) which would be based on equipment efficiency and performance. Waste companies too will be key influencers and actors in the further development of waste resource management from commercial kitchen operations.

Given the aforementioned predicted scenarios, the supply chain gaps that exist today will need to be considered and eradicated, or at least reduced, in light of the further consolidation and control that equipment operators will need from their value chain. Studies* are available that give an insight into the manufacturer, consultant, dealer issues that exist.

Now, let’s get back to those “sights.” Insight is what makes your company truly unique. If your competitors have assets and capabilities that are very similar in nature to yours, then they can certainly replicate and execute your strategy, or more disturbing, even improve on it. True insight is very company specific – it identifies those assets that are rare, distinctive, and valuable to your company. They are assets that companies can, and should, highly leverage in the marketplace.

Cross-Sight is a company’s ability to identify those assets that are uniquely valuable to a company and/or assets with unique value that other companies are simply unable to perceive, that could be aggressively deployed by your organization. Think of Apple Computer and the numerous technology acquisitions and product developments that it has made over the years that have made Apple products leaders within the consumer electronics field.

All three of these “sights”: foresight, insight and cross sight, when combined and used together, will allow companies to create a continuous succession of value-creating strategies. Foresight, specifically as it applies to future demand, the use of new and existing technologies, and industry and consumer trends will highlight those areas in which companies should be searching for cross-sight. Conversely, insight, regarding a company’s unique assets, will help focus a company’s search for foresight and cross-sight. And finally, cross-sight will help reveal those valuable complimentary products and services, which in turn will highlight the domain of foresight.

Value creation for food service industry customers should focus squarely on their experiences and solutions to their problems. Study after study in this industry has shown that what operators are looking for from their up-stream channel constituents – and very few, if any companies are actually providing this – are well designed experiences and solutions to their problems. If you do this through the use of the “Sights” Model you will create true and sustainable value for your customers.

Companies who do an excellent job of this put themselves inside their customers’ businesses (in some cases, literally) and then embrace the outcomes that they (their customers) are trying to achieve. The great Austrian born management guru, Peter Drucker, noted that knowledgedriven innovations are “almost never based on one factor but rather on the convergence of several different kinds of knowledge.” The initial knowledge that is “born” often results in a tremendous amount of activity and excitement, but it is not until all pieces of the knowledge puzzle have been “discovered” and put into their appropriate places that true progress can actually be achieved.

External forces and drivers — Data management teams will be as essential to a business in 2015 as marketing, sales, accounts, and operations teams are today. We are seeing this start through Building Information Modeling (BIM) which allows cloud based design using 3 dimensional rendered models to which data is tagged. This will start to be a requirement in public sector projects from 2016. By more efficient collaboration between the designer and contractors, BIM will reduce procurement costs by 20%. Having a full inventory of the equipment in the building, the day to day operation and performance will be managed including the kitchen. The direct product profitability of the equipment will be continually evaluated and managed to ensure that its contributing to the operator’s profits. This will also assist with the management of food costs and the management of food waste in an effort to contain overall costs.

The equipment companies that are closest to the foodservice operator will have the opportunity to gather and interpret data on the activity in sites and with the consumer. Thus, the benefits of “big data” and the “internet of things” will inevitably grow. Manufacturers in the “new” value chain will have specialists within their own business who can interpret, use the data, and turn it into valuable, actionable information. This will provide competitive advantage at all levels in the chain but especially with the foodservice operator’s management team. This interdependence will provide a greater understanding of operator and consumer habits, and link this to the equipment’s operational needs. The use of data in this way will increase the need for transparency and trust between the equipment manufacturers and the food service operators.

The equipment companies that have access to this data, combined with the commitment to interrogate it effectively, will have the edge over their competitors. They will also have the opportunity to develop new equipment and services based on detailed knowledge from the marketplace; this equipment “black box” of information will include utilities use, patterns of use, optimum labour requirements and so on. With all of this management information available it will get to the point where the direct product profitability of a menu item will be driven by the information on the equipment used to prepare it; the utilities used in its preparation and service; the consumables used, and the labour required. If carbon is to be the currency of the future the use of data in this way can provide a carbon footprint for the equipment, the kitchen and the menu.

The availability and use of data in the proposed new value chain will mean that equipment companies will have the opportunity to develop new products which will subsequently provide access to even more data which they will need to help turn into actionable information. This, when linked to the identification and transfer of innovative ideas and technologies from other industries, will complement a company’s own research and development initiatives.

There is a profitable and rewarding outlook for those companies who can sustain their strategies with ever closer engagement with specifiers and foodservice operators. There will be the inevitable and unforeseen disruptive influences to business (as there always has been) but an enhanced value proposition that is data focused will be key to effective business development.

There is a profitable and rewarding outlook for those companies who can sustain their strategies with ever closer engagement with specifiers and foodservice operators. There will be the inevitable and unforeseen disruptive influences to business (as there always has been) but an enhanced value proposition that is data focused will be key to effective business development.

In summary, the transition from a supply chain to the value chain will, and can only be achieved by those companies that show the ability to engage and evolve their management thinking and practices. Companies that are able to demonstrate the ability to flex their resources and actively engage all of their channel constituents in a meaningful and transparent way will become part of the value chain that is already beginning to evolve.

About the authors: Douglas K. Fryett is the founder of the Fryett Consulting Group a global consulting firm specialising in strategy development, strategy execution, and proprietary market research for companies and organizations in the hospitality / food service industries. He is also a frequent speaker at industry conferences and events. Keith Warren is the chair of the technical committee of EFCEM (European Federation of Catering Equipment Manufacturers) and Director of C.E.S.A. (Catering Equipment Suppliers Association), the leading UK industry trade association. Keith has also taken on major leadership roles in various catering associations throughout Europe and is viewed as a key thought leader within the industry.